- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

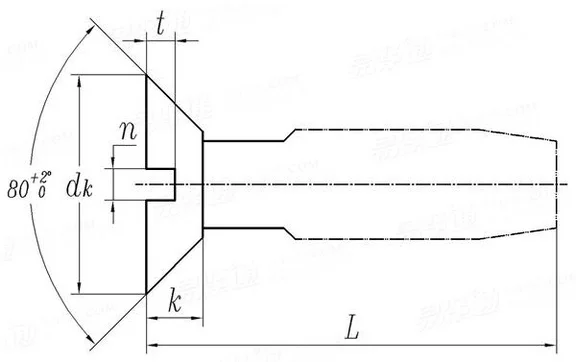

82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws [Table 9]

For precise and reliable tapping operations, choose 82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws. Compliant with ASME B 18.6.3 - 2013 standards, these screws ensure optimal performance and durability in various applications.

Model:ASME B 18.6.3

Send Inquiry

Product Description

Optimized Design: ASME B 18.6.3 - 2013 specifies 82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws, featuring an optimized design for efficient tapping operations. The undercut design enhances thread formation, promoting secure and reliable fastening in various materials.

Enhanced Stability: With a flat countersunk head and an 82° angle, these screws ensure flush installation, minimizing surface protrusion and optimizing the appearance of assembled components. This design feature also enhances stability and prevents snagging in applications where aesthetics and functionality are crucial.

Precision Tapping: Engineered for precision tapping, these screws deliver consistent and accurate thread formation, facilitating smooth installation and reliable fastening. The slotted head design enables efficient tightening and removal, enhancing productivity in assembly processes.

Durable Performance: Crafted from high-quality materials, these tapping screws offer durability and resilience in demanding environments. They withstand torque and shear forces, providing long-lasting performance and contributing to the structural integrity of assemblies.

|

①,Edge of head may be rounded or flat. ②,Screws of these lengths and shorter shall have undercut heads. ③,● Type AB thread-forming , see table [Table 40] ◆ Type A thread-forming, see table [Table 42] ▲ Type B and BP thread forming, see table [Table 41]; Type BF and BT thread cutting, see table [Table 43] ■ Type C thread forming, see table [Table VI-1]; Type D, F, G and T thread cutting, see table [Table 44]; and Type TRS thread-rolling ,see table [Table 45] |

![82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws [Table 9] 82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws [Table 9]](https://i.trade-cloud.com.cn/upload/7135/din-7972-4-1831314.jpg?x-oss-process=image/format,webp)

![82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws [Table 9]](https://i.trade-cloud.com.cn/upload/7135/din-7972-6-2727900.jpg?x-oss-process=image/format,webp)

![82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws [Table 9]](https://i.trade-cloud.com.cn/upload/7135/din-7972-1-386256.jpg?x-oss-process=image/format,webp)

![82° Slotted Undercut 82-deg Flat Countersunk Head Tapping Screws [Table 9]](https://i.trade-cloud.com.cn/upload/7135/din-7972-3-4584763.jpg?x-oss-process=image/format,webp)

![80° Slotted Undercut Oval Countersunk Head Tapping Screws [Table 11] 80° Slotted Undercut Oval Countersunk Head Tapping Screws [Table 11]](https://i.trade-cloud.com.cn/upload/7135/80-slotted-undercut-oval-countersunk-head-tapping-screws-table-11-_1713.jpg?x-oss-process=image/format,webp)

![82° Dimensions of Slotted Oval Countersunk Head Tapping Screws [Table 7] 82° Dimensions of Slotted Oval Countersunk Head Tapping Screws [Table 7]](https://i.trade-cloud.com.cn/upload/7135/82-dimensions-of-slotted-oval-countersunk-head-tapping-screws-table-7-_623583.jpg?x-oss-process=image/format,webp)

![82° Slotted Flat Coutersunk Head Tapping Screws [Table 1] 82° Slotted Flat Coutersunk Head Tapping Screws [Table 1]](https://i.trade-cloud.com.cn/upload/7135/82-slotted-flat-coutersunk-head-tapping-screws-table-1-_30442.jpg?x-oss-process=image/format,webp)

![Hex Washer Head Tapping Screws - Type A Thread Forming [Table 40] Hex Washer Head Tapping Screws - Type A Thread Forming [Table 40]](https://i.trade-cloud.com.cn/upload/7135/hex-washer-head-tapping-screws-type-a-thread-forming-table-40-_56817.jpg?x-oss-process=image/format,webp)