- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

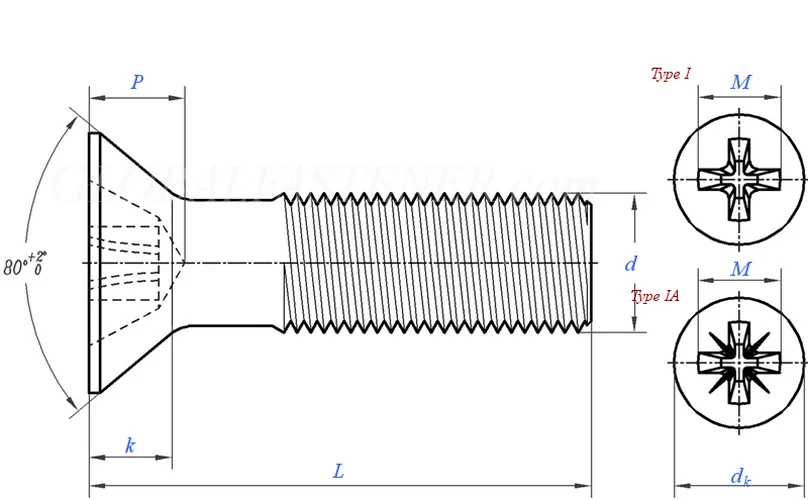

82° Cross Recessed Countersunk Head Screws [Table 2] (ASTM F837, F468)

Achieve secure and flush fastening with 82° Cross Recessed Countersunk Head Screws compliant with ASME B 18.6.3 - 2013 standards. Built for durability and precision, they offer reliable solutions for various applications.

Model:ASME B 18.6.3

Send Inquiry

Product Description

Secure Fastening: ASME B 18.6.3 - 2013 compliant 82° Cross Recessed Countersunk Head Screws provide secure fastening in various applications. Their countersunk head design ensures a flush finish, minimizing snagging and offering a sleek appearance.

High-Quality Materials: Manufactured from ASTM F837 and F468 compliant materials, these screws offer exceptional durability and corrosion resistance. They maintain their integrity even in challenging environments, ensuring long-term performance.

Precision Engineering: Engineered to precise specifications, these screws provide a precise and reliable fit, reducing the risk of stripping or loosening over time. This ensures a stable and secure fastening solution for a wide range of materials and applications.

Versatile Application: Suitable for both indoor and outdoor use, these screws are ideal for woodworking, furniture assembly, and construction projects. Their versatility and dependable performance make them a valuable addition to any toolkit.

|

①,Edge of head may be rounded or flat. ②,Screws of these lengths and shorter shall have undercut heads. ③,7#, 14#, 16#, 18#, 20#, 24# are for tapping screws only. ④,9/16,5/8,and 3/4 for machine screws only. ⑤,Machine Screw Length of Thread 1) Sizes No.5 and smaller. Screws of nominal lengths equal to three diameters and shorter shall have full-form threads extending to within one pitch (thread) of the bearing surface of the head, or closer, if practicable. Nominal lengths greater than three diameters, up to and including 1-1/8 in., shall have full-form threads extending to within two pitches (threads) of the bearing surface of the head, or closer, if practicable. Screws of longer nominal lengths shall, unless otherwise specified, have a minimum length of full-form thread of 1 in. 2) Sizes No.6 and smaller. Screws of nominal lengths equal to three diameters and shorter shall have full-form threads extending to within one pitch (thread) of the bearing surface of the head, or closer, if practicable. Nominal lengths greater than three diameters, up to and including 2 in., shall have full-form threads extending to within two pitches (threads) of the bearing surface of the head, or closer, if practicable. Screws of longer nominal lengths shall have a minimum length of full-form thread of 1.5 in. unless otherwise specified. ⑥,Machine Screw Material 1)non-heat-treated low carbon steel, such as1006 through 1038 2)When hardened machine screw are specified, they shall be made from low or medium carbon steel, such as 1018 through 1038, with or without boron, through-hardened to Rockwell C25-38 |

![82° Cross Recessed Countersunk Head Screws [Table 2] (ASTM F837, F468) 82° Cross Recessed Countersunk Head Screws [Table 2] (ASTM F837, F468)](https://i.trade-cloud.com.cn/upload/7135/din-965-13-1834891.jpg?x-oss-process=image/format,webp)

![82° Cross Recessed Countersunk Head Screws [Table 2] (ASTM F837, F468)](https://i.trade-cloud.com.cn/upload/7135/din-965-6-2117303.jpg?x-oss-process=image/format,webp)

![82° Cross Recessed Countersunk Head Screws [Table 2] (ASTM F837, F468)](https://i.trade-cloud.com.cn/upload/7135/din-965-15-3271384.jpg?x-oss-process=image/format,webp)

![82° Cross Recessed Countersunk Head Screws [Table 2] (ASTM F837, F468)](https://i.trade-cloud.com.cn/upload/7135/din-965-8-4538169.jpg?x-oss-process=image/format,webp)